-

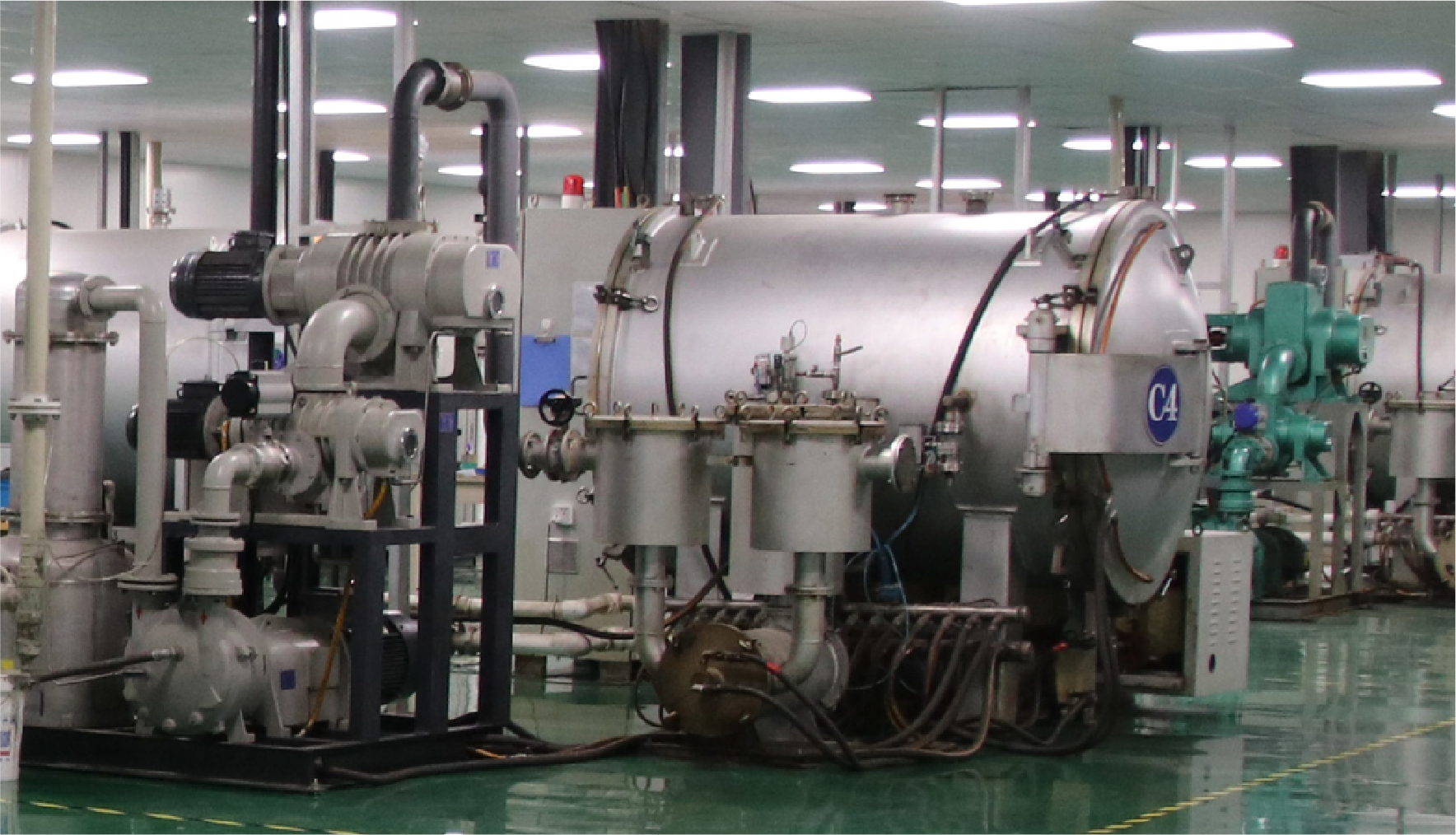

Sintering furnace

1. Infrared temperature measurement and control system, equipped with infrared temperature measurement and control system, can display and PID automatically control the temperature inside the furnace in real time to ensure stable product quality.

2. High operating temperature, with a maximum temperature of 3000 ℃, can work between 2600-2800 ℃.

3. Using carbon felt as insulation material makes it easy to replace carbon pipes.

4. The heating time is short, up to 200 ℃/hour.

5. The furnace body has good sealing and low loss of protective gas.

-

Automatic circular cutting machine

The operation of the circular knife machine is more convenient, the process matching is more reasonable, and the production efficiency and yield are higher. At present, our company has 10 circular cutting machines with positions ranging from 8 to 24.

-

CCD automatic printing machine

Printing ink and water-based adhesive on shading and reflective films

using high-precision CCD positioning module

using R-TO-R printing

accuracy can be controlled within ± 0.2mm - unmanned or minimally populated -

CCD high-precision automatic die-cutting machine

Used for forming light blocking, reflective and light guiding films

- coil feeding, automatic alignment equipment

fast processing efficiency, environmental protection, low energy consumption

-environmentally friendly physical processing, pollution-free, in line with carbon neutrality goals

- CCD alignment accuracy can reach ± 0.2mm

-efficiency improvement of over 400% -

LGP hot press machine

Using a mold to heat press a roll of light guide dots on the surface of the substrate for feeding, the equipment automatically aligns and processes quickly, environmentally friendly, and consumes less energy. Physical processing is environmentally friendly and pollution-free, meeting the goal of carbon neutrality. Through photolithography molds and heat transfer processes, the product is more stable with a dot diameter of ± 5 μ m and a dot depth of ± 2 μ m

-

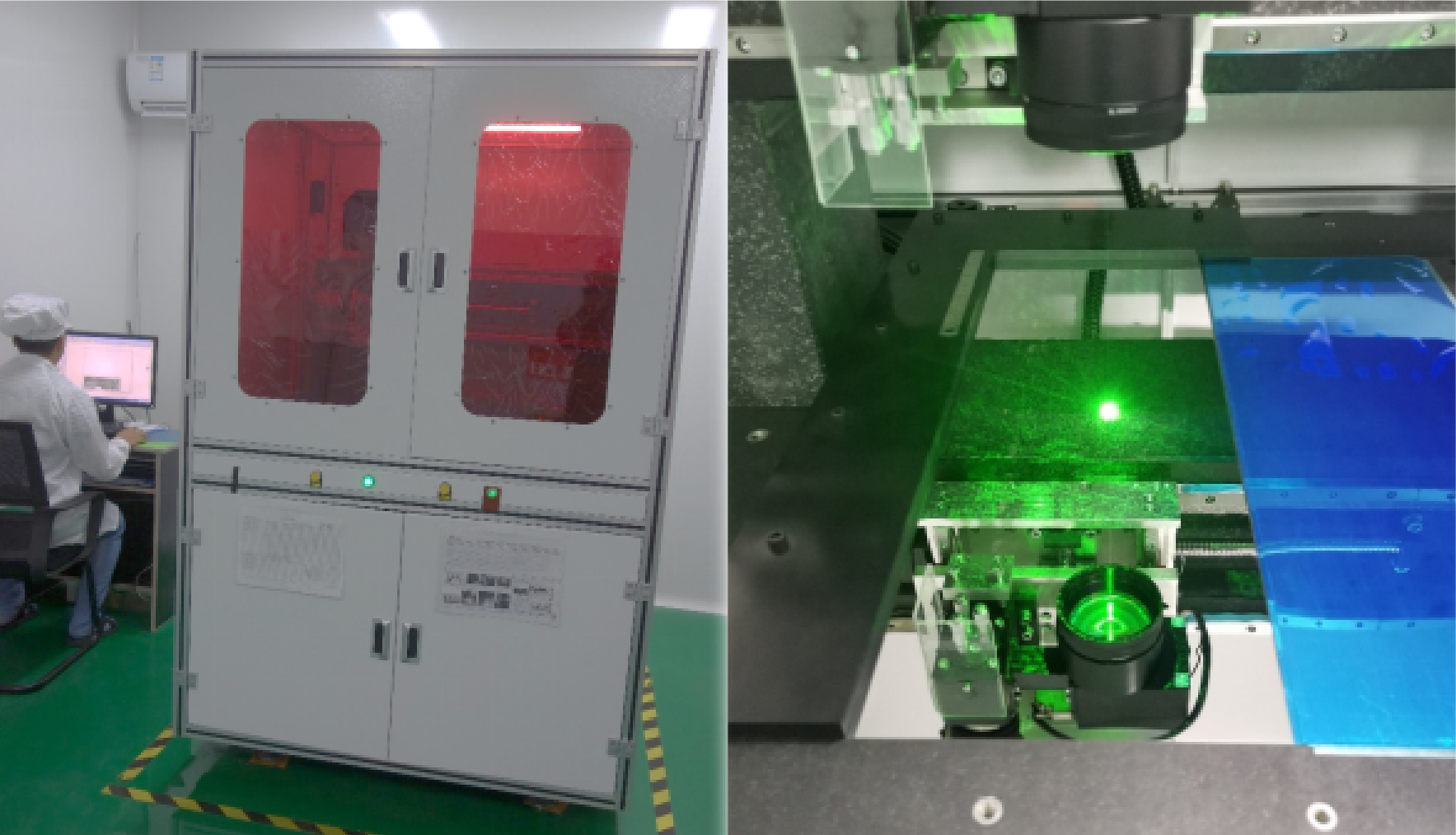

Optical dot lithography machine

Using laser to carve light guide points on the surface of the mold substrate, all imported laser accessories work stably. Low heat green laser is suitable for LGF industry control accuracy in the μ level. The machine has strong adaptability to the working environment and can be used for photolithography on SUS 304 # mirror steel plate .